High performance spring assembly for the automotive industry

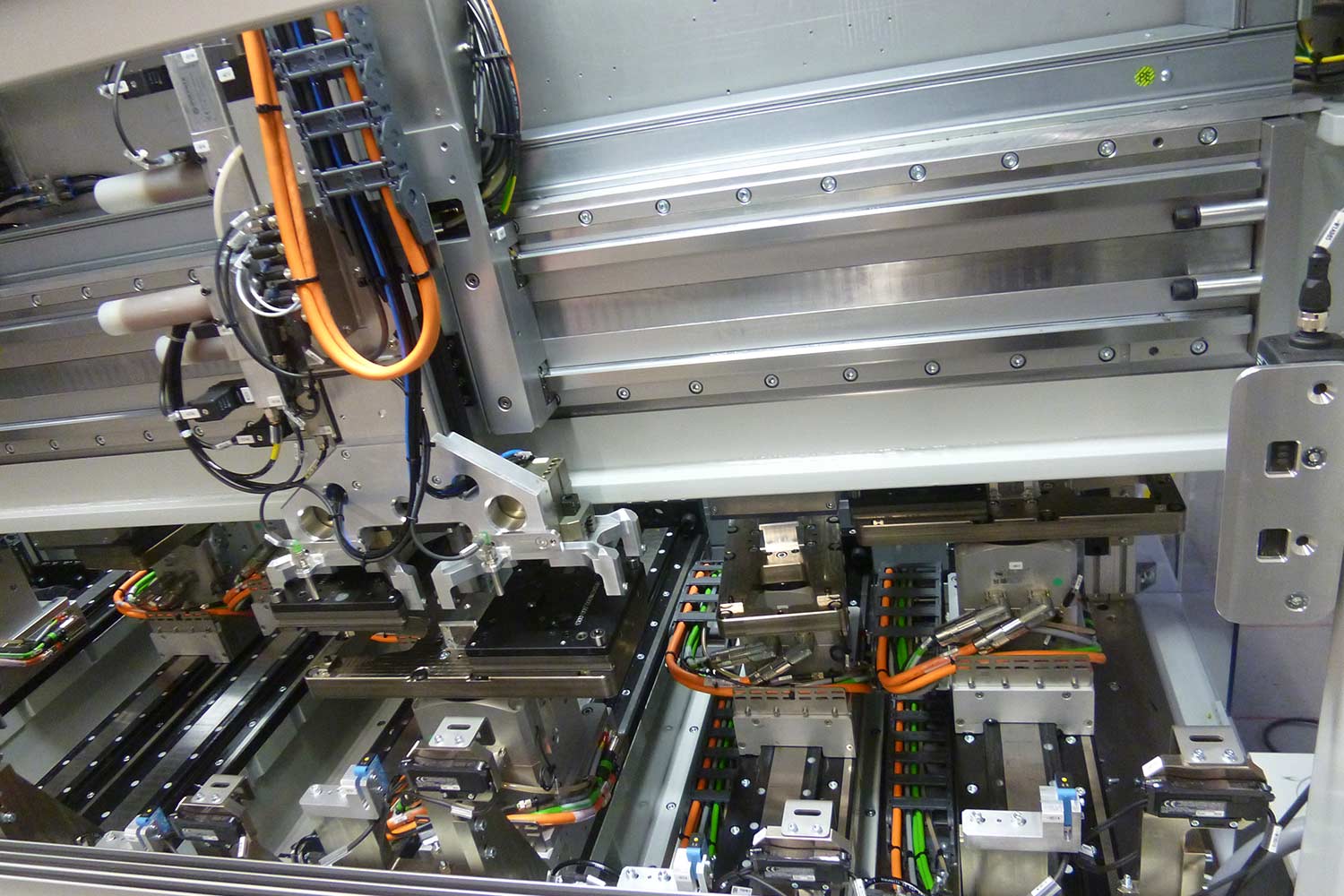

Our spring assembly system has exceeded the high requirements of a customer from the automotive industry! With 8 processing stations, 24 axes and a sorting rate of 600 springs per minute, the system is highly dynamic and extremely compact in the smallest of spaces. The challenge was the high assembly frequency and the supply of contact springs in the correct position for driver assistance systems. But our system has mastered this challenge, making it unique on the market. We adapted to changing customer requirements during the project and worked successfully with another axle manufacturer. The result is a great finished product with guaranteed lifespan requirements of 30 million cycles. If you are looking for a reliable spring assembly system for the automotive industry, you’ve come to the right place!

THE TASK

- Sorting and supply of contact springs in the correct position for driver assistance systems

- Assembly frequency of 600 springs per minute with above-average availability

- Highly dynamic and compact in the tightest of spaces

THE SOLUTION

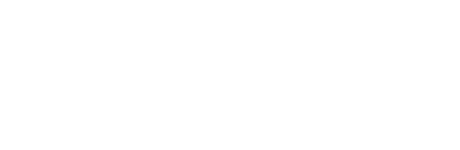

- 8 processing stations

- 24 axes on 6 square metres

- 24 linear motor axes and directly driven rotating units

- Guaranteed WEISS component service life requirement of 30 million cycles

AREAS OF APPLICATION

- Automotive industry

CUSTOMER BENEFITS

- Intelligent production planning

- Continuous component supply

- Increased productivity