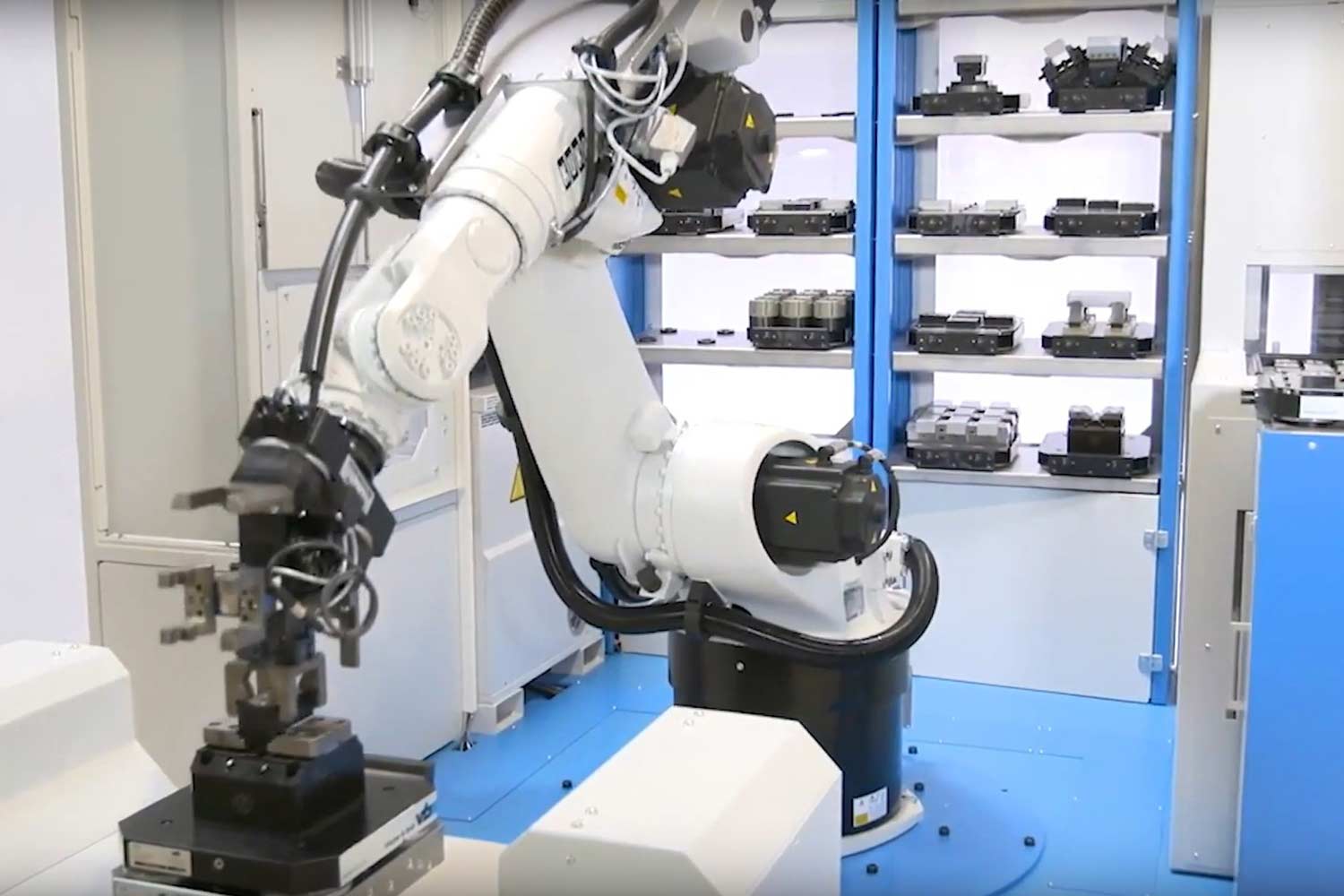

Workpiece and pallet handling for milling up to 300 kg

The modular robot cell allows the workpiece to be placed on a clamping device, the clamping device to be handled and a tool to be inserted into the spindle of the machine tool. The workpieces are fed using the integrated palletising systems PTS 6410 or PTS 6440. The clamping devices can be prepared at the preparation station and then processed in a time-saving and continuous manner. MAFU Automation provides ideas and solutions for the intelligent automation of manufacturing and machining processes. Based on this experience, a modular, compact, complete solution that is unique on the market was created for the handling of pallets, workpieces and tools, including clamping technology. The cell ensures the automated processing of workpieces up to 300 kg in small and medium batch sizes with pallet sizes up to 500 x 500 mm.

AREAS OF APPLICATION

- Designed for individual parts and series production

- Connection to any machine tool possible

POSSIBLE MAIN PARALLEL WORK

- Parts cleaning

- Deburring

- Part measurement with transfer of the measured value to the machine

SYSTEM CHARACTERISTICS

The key benefits of the robot cell are its simple and user-friendly operation and its modular structure. The robot systems also stand out thanks to their energy efficiency, space-saving design, quick and easy conversion and ease of maintenance. Additional functions such as part recognition with camera and special solutions in line with customer requirements are optionally available. Additional tool holder positions, for example for tools with special lengths, can be defined in the robot cell and inserted into the machine tool.

Even machines without media rotary feedthroughs can be automated with this robot cell. In this case, the devices are opened and closed using the robot and a torque wrench. Connection to any machine tool is possible. Interfaces: Profinet, Profibus or digital. The system control is implemented via a master computer system from the partner company Procam.

RFID CHIP FOR PALLET IDENTIFICATION

This chip can be integrated into exchangeable pallets for identification. The current data is adjusted using a write-read device. This helps us ensure error-free communication between the machine tool and the robot.

I am looking forward to your contact.