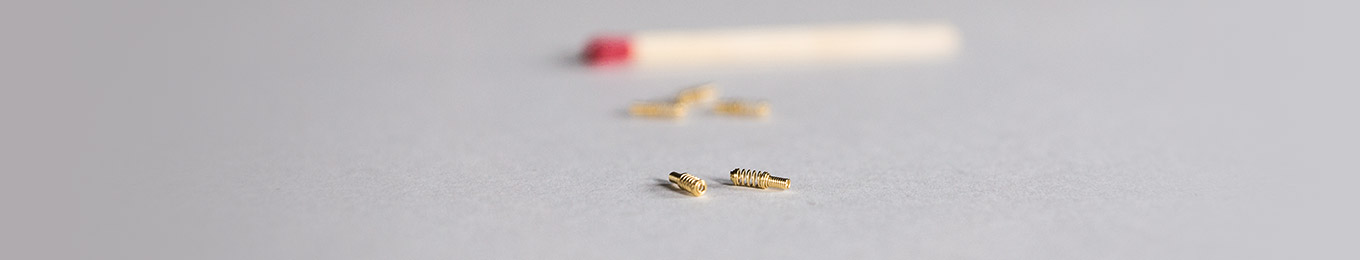

Separation systems

The patented separation systems from MAFU Automation ensure that parts are available at the required locations according to their further processing. We provide our customers with manual, semi-automated and fully automated solutions with integrated self-suppression, depending on their requirements.

Separation with service flap

- Separation modules in a compact design, for the springs arranged one behind the other in the tube

- Separating pins with end position monitoring

- Blowing impulse for blow-feeding individual springs as well as sensory monitoring

- Service flap for quick troubleshooting without tools possible.

Separation with service flap and NOK slider

- Separation module in a compact design, for the springs arranged one behind the other in the tube

- Component-friendly separation using a spring-loaded separation pin

- Automatic self-suppression including rejection unit

- Separating pins with end position monitoring

- Blowing impulse for blow-feeding individual springs

- Version with surface clamping of the springs possible

- Service flap for quick troubleshooting without tools possible

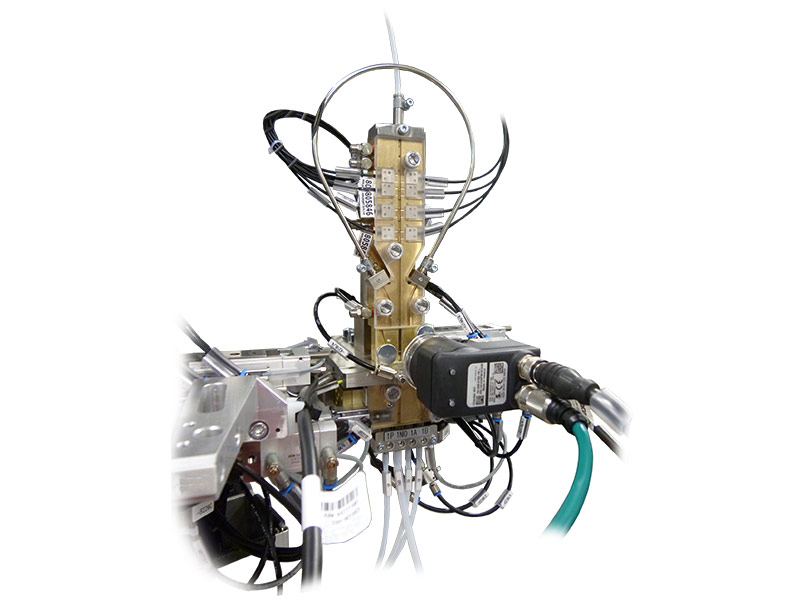

Cascade isolation with looping and position detection

- Cascade system with several cascade chambers

- Monitoring of the individual cascade chambers

- Component testing using a vision system in an additional test chamber

- Incorrectly positioned parts are rotated by 180° using a looping section

- Looping separation ensures 100% processing of springs

Kaskadenvereinzelung mit Drehmodul und Lageerkennung

- Kaskadensystem mit mehreren Kaskadenkammern

- Überwachung der einzelnen Kaskadenkammern

- Bauteilprüfung durch Vision-System in zusätzlicher Prüfkammer

- Falsch liegende Teile werden mittels Drehmodul aktiv gedreht

- Vereinzelung mit Drehmodul gewährleistet eine 100%ige Verarbeitung der Bauteile

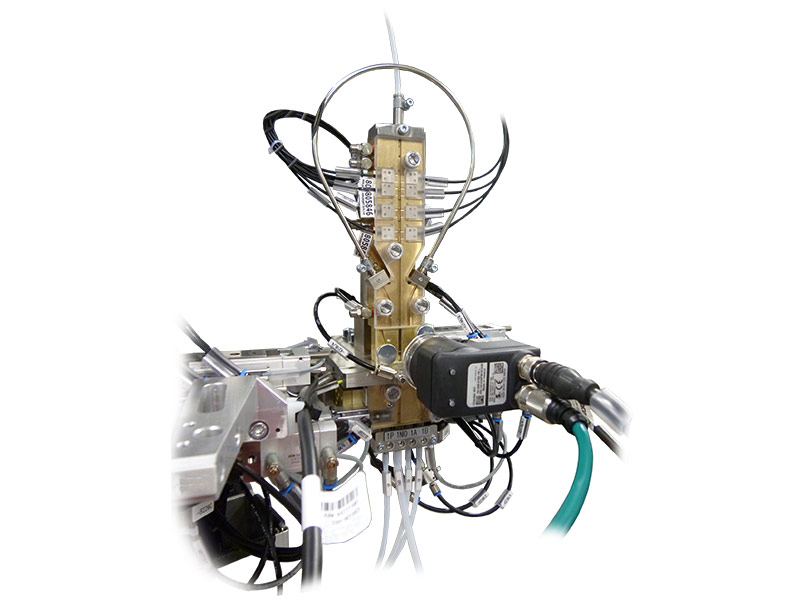

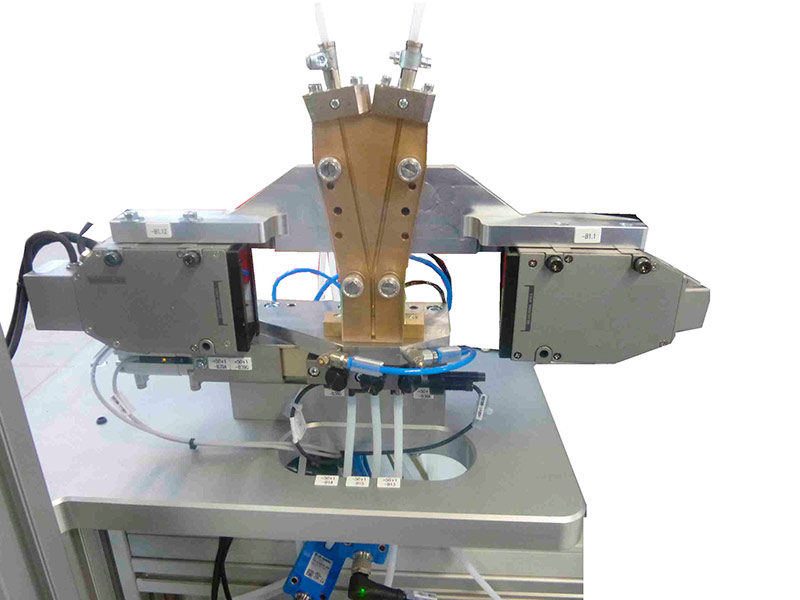

Special separation with measuring tools

- Separation with integrated measuring tool

- All separation modules can be equipped with additional measuring tools for component testing

Example shows:

- Incl. measuring tool - light band micrometer, measuring range 0.3 - 30 mm, measuring accuracy +/-2μm, repeatability +/- 0.15 μm.

- Synchronisation unit with 3 tube outlets. Spring 1 / Spring 2 / nOK outlet – can be expanded as required

Y-shaped separation unit

- Manual removal adapter enables easy manual removal of the springs

- An adapter for each supply tube to supply the springs.

- Easy removal of the springs using a rocker

- Incl. sensor as a trigger signal for separation

- Manual removal adapter helps upgrade manual workstations

Manual removal adapter

- Manual removal adapter enables easy manual removal of the springs

- An adapter for each supply tube to supply the springs.

- Easy removal of the springs using a rocker

- Incl. sensor as a trigger signal for separation

- Manual removal adapter helps upgrade manual workstations

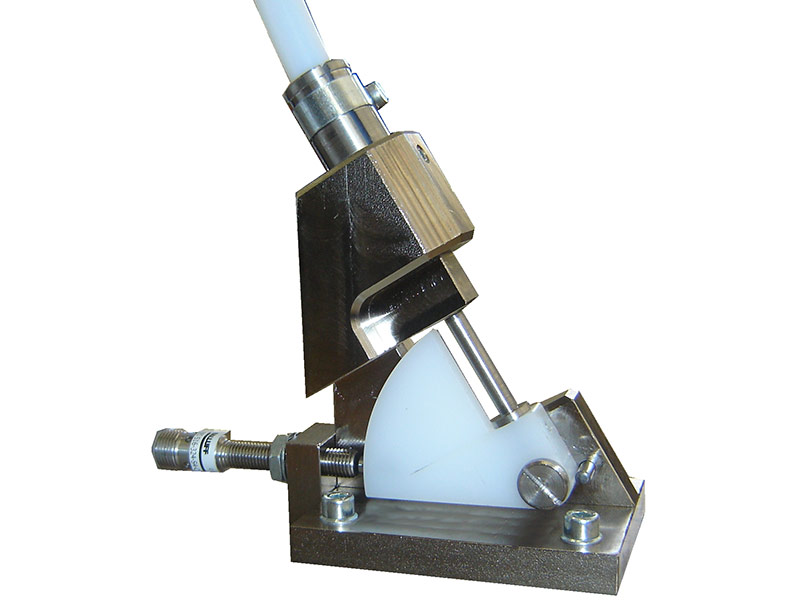

Hand filling pen

- Inserting springs into the component using a hand filling pen

- The separation signal is triggered by a button on the hand filling pen

- In addition, an insertion aid in the form of a setting tube is attached

- Including sensors for setting the spring or dropping the spring into the component

- Filling pen is used to upgrade manual workstations

I am looking forward to your contact.